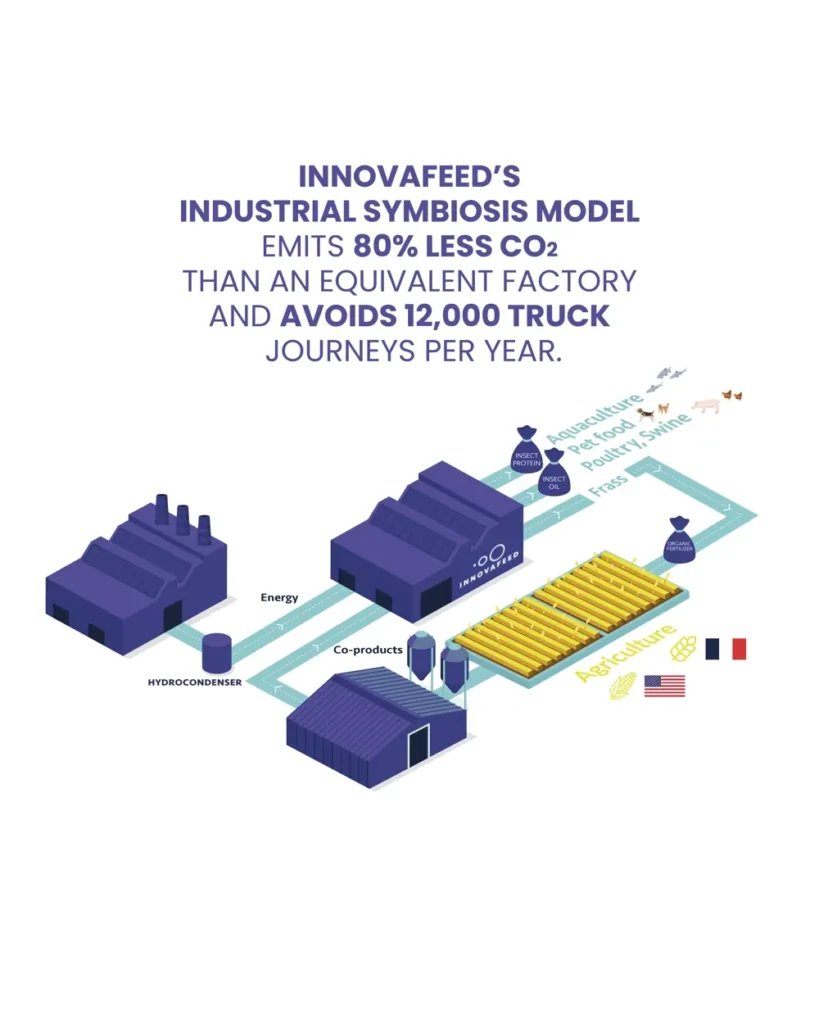

Preserving our planet is a necessity and an issue that we must not ignore. At Innovafeed we consider that sustainability, far from being a cost, is an argument for economic competitiveness. We believe that it is our responsibility to invent the production methods of tomorrow combining performance and sustainability so that each of us can have access to sustainable and quality products.

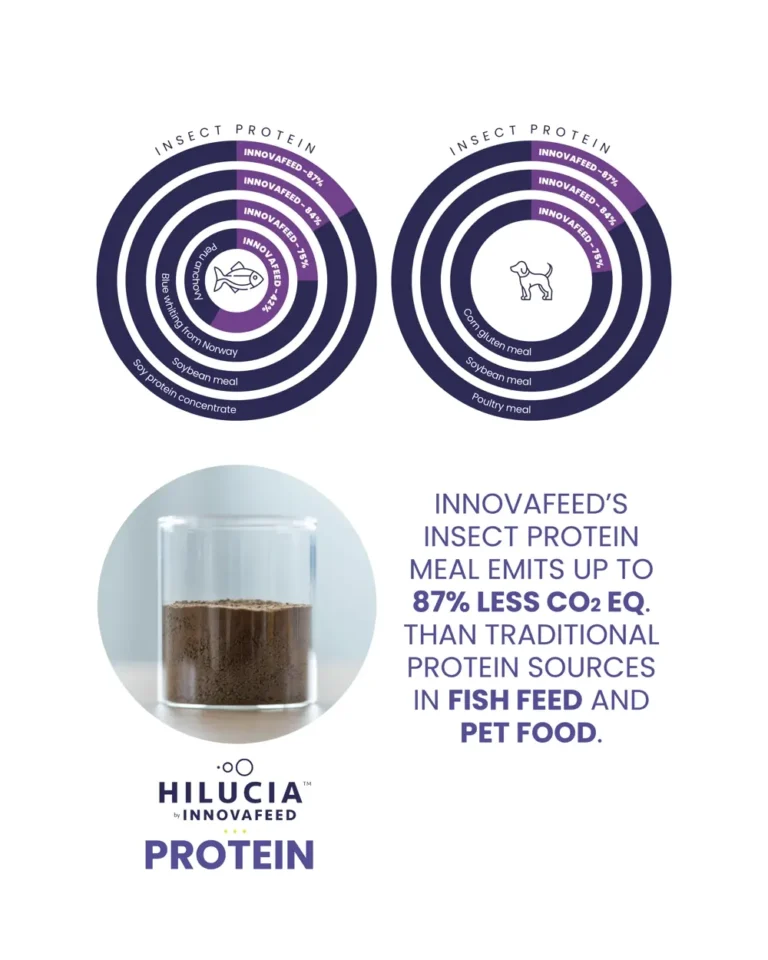

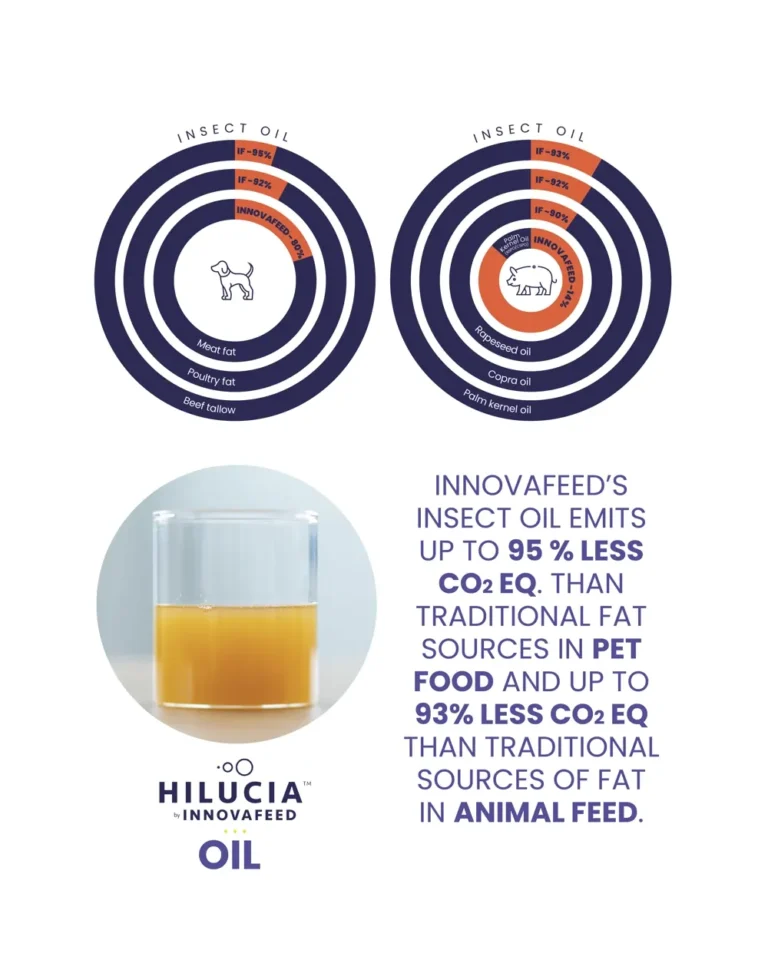

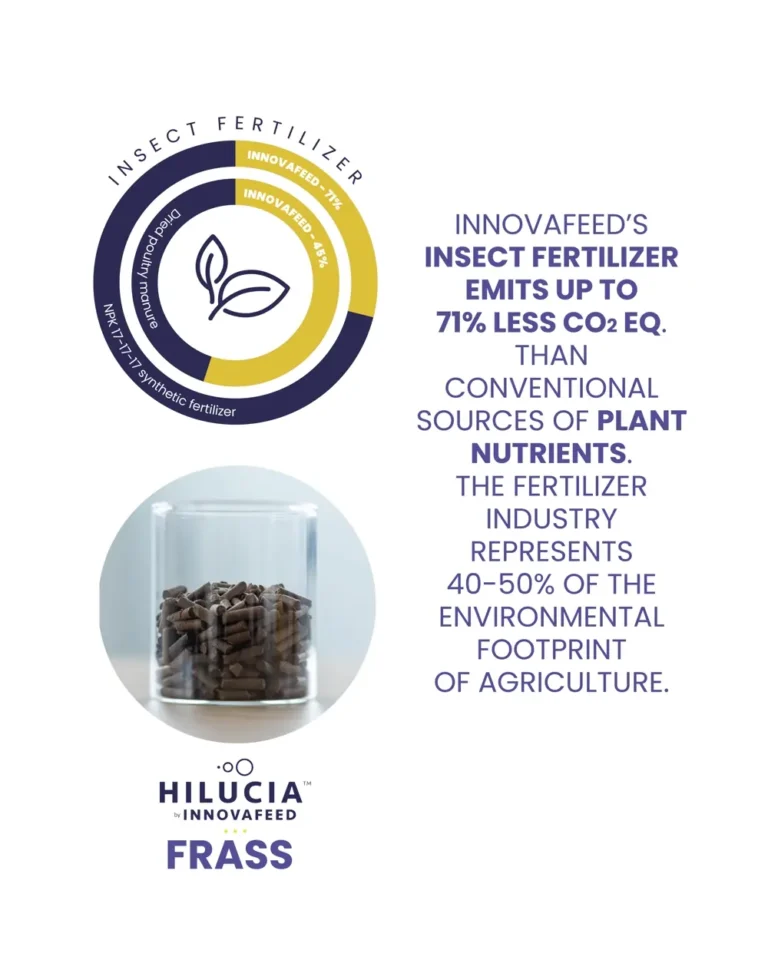

We scientifically assess the environmental impact of the models and products we develop in order to be able to communicate rigorously and transparently on our environmental performance as well as to continue to improve it.

Our environmental impact is thus assessed and analyzed by independent experts through the realization of Life Cycle Analyzes (LCA, the best tool in terms of global and multi-criteria assessment of environmental impacts).

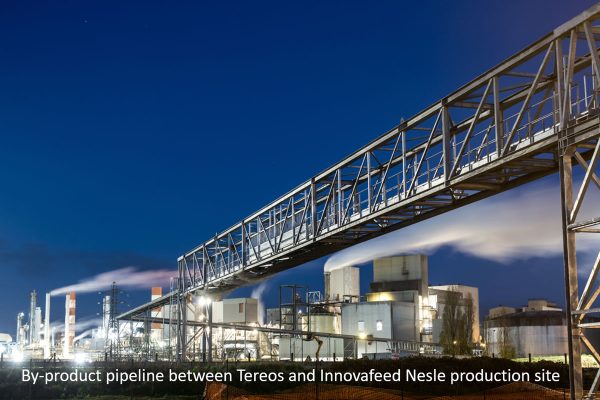

Thanks to these LCAs, we have thus developed and deployed a production model that is unique in the world for products with demonstrated and quantified environmental performance.